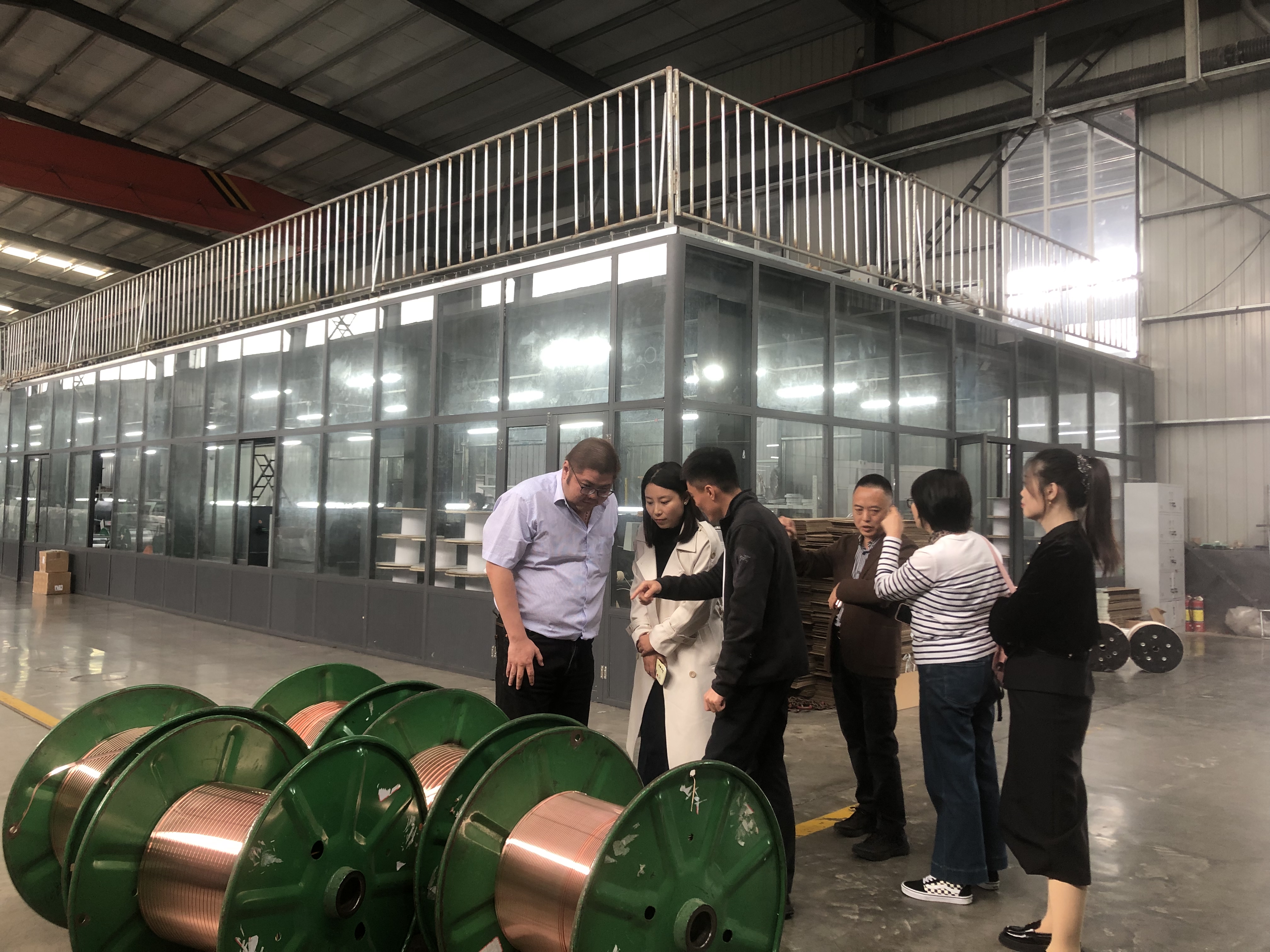

Recently, an Indonesian client delegation visited our facility to conduct on-site product inspections focusing on three core categories: transformers, grain-oriented silicon steel, and iron cores. The visit aimed to verify compliance with Indonesian technical standards and cooperative agreements.

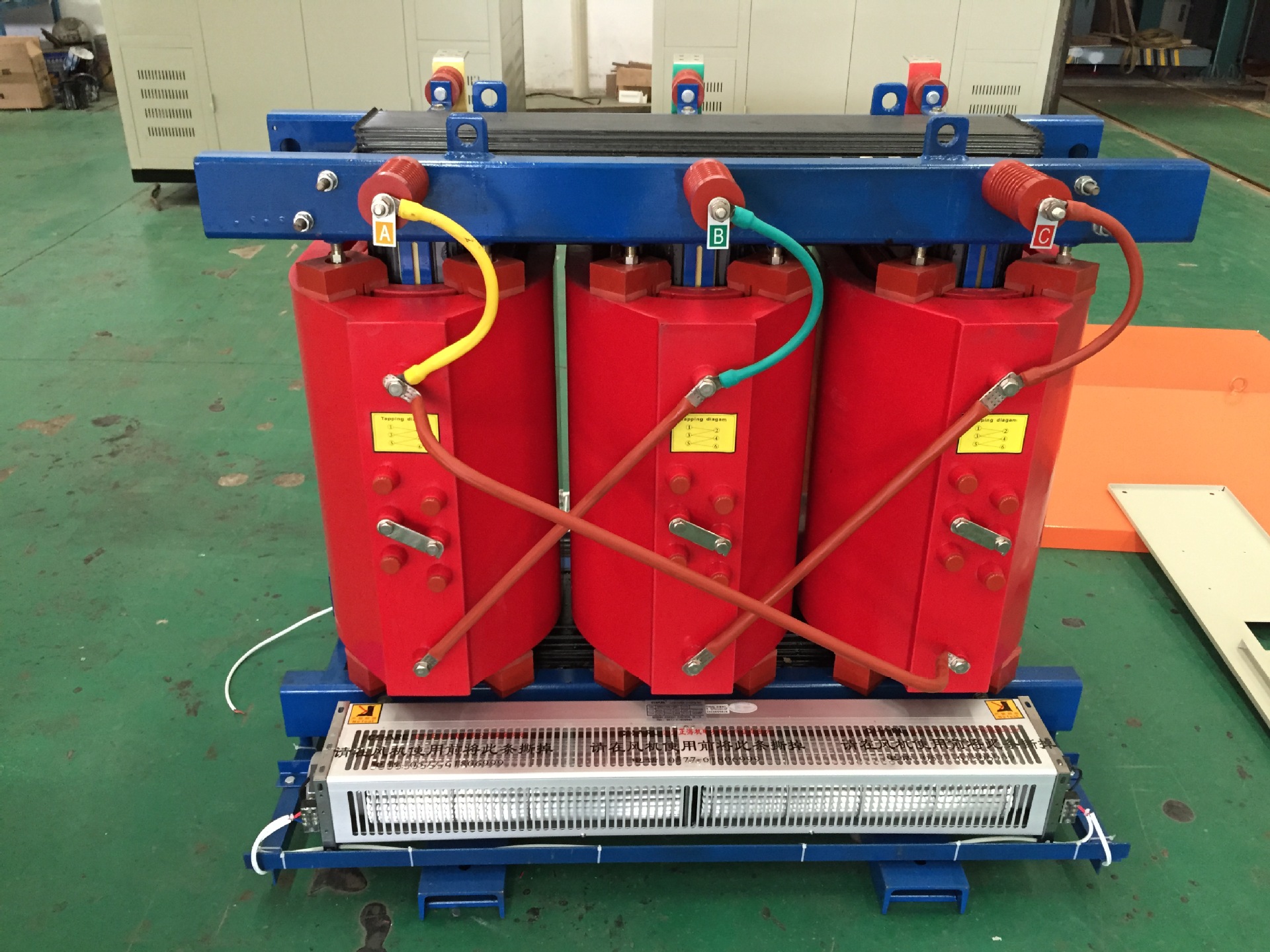

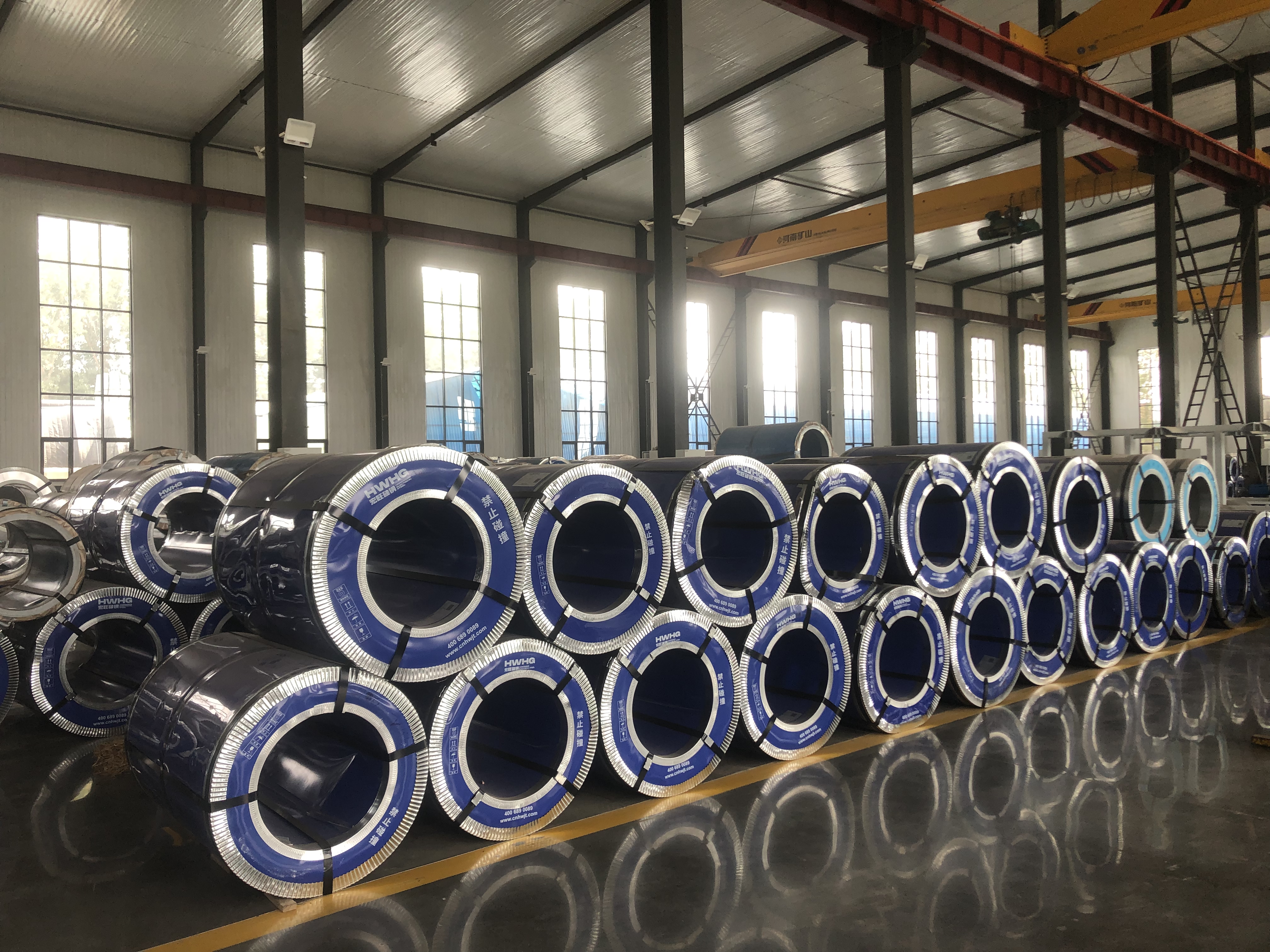

During the inspection process, the client team performed systematic verifications of key performance indicators. In the transformer section, particular attention was paid to coil winding density, insulation thickness, and load loss test data to ensure alignment with local grid requirements. For grain-oriented silicon steel, specialized equipment was employed to measure magnetic properties and surface finish, confirming the material's suitability for tropical climate applications. During iron core inspection, detailed assessments were made regarding lamination alignment, fastening techniques, and magnetic circuit design to validate long-term operational reliability.

Our engineering team provided comprehensive support throughout, offering real-time data interpretation and demonstrations of production process controls. The delegation acknowledged the product quality and standardized management systems. This successful inspection has strengthened our collaborative partnership, establishing a solid foundation for continued contribution to Indonesia's energy sector through our products.