-

Mobile Version

Scan with Mobile

- Member Center

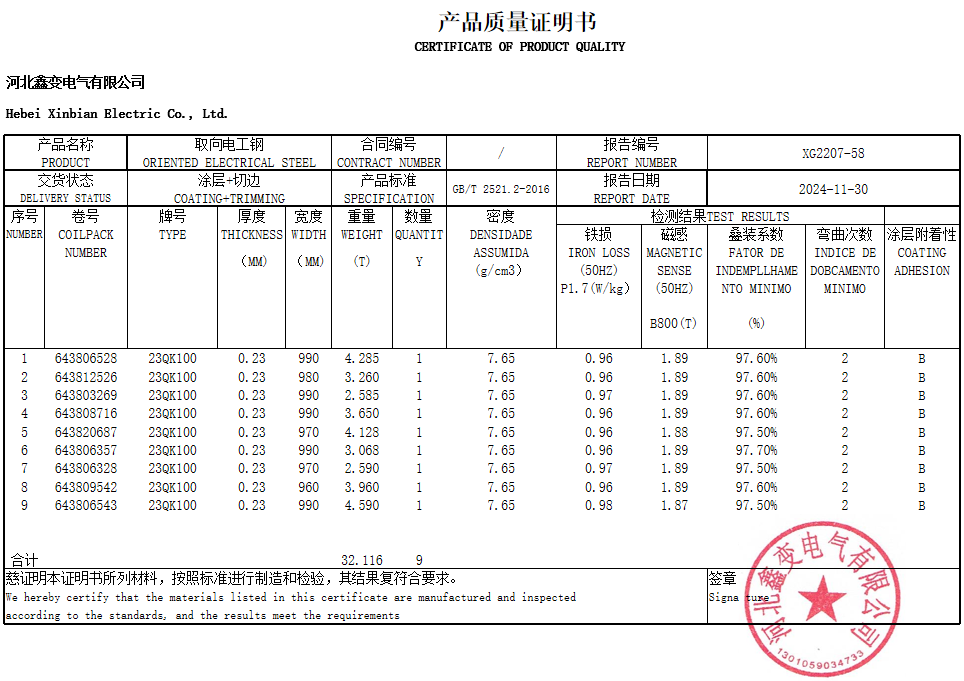

23QK100 grain-oriented silicon steel

Performance Features

• High Permeability and Low Loss: It has relatively high permeability, enabling efficient magnetic field conduction. In an alternating magnetic field, the hysteresis loss and eddy current loss are low, which can effectively reduce power loss and improve the energy efficiency of equipment.

• High Saturation Magnetic Induction Intensity: With a relatively high saturation magnetic induction intensity, it can achieve a higher magnetic flux density within a smaller volume, increasing the power density of equipment. This allows motors, transformers and other equipment to output greater power under the same volume.

• Good Thermal Stability: Its magnetic properties remain stable within a certain temperature range, ensuring the stable operation of equipment under different working temperatures and prolonging the service life of the equipment.

• Excellent Mechanical Properties: It has relatively high strength and hardness, which can resist external stress and deformation, improving the stability and reliability of the material.

Production Process

• Strict Composition Control: Precisely control the contents of elements such as silicon and carbon to ensure the stability of the chemical composition and obtain good magnetic properties and processing performance.

• Hot Rolling and Normalizing Treatment: The steel billet undergoes hot rolling to improve the microstructure and then undergoes normalizing treatment to refine the grains.

• Cold Rolling and Annealing Process: Multiple passes of cold rolling are carried out accompanied by intermediate annealing. The process parameters are strictly controlled to make the grain orientation more consistent and improve the magnetic properties.

• Decarburization Annealing and High-temperature Annealing: These processes further improve the magnetic properties, reduce iron loss and increase magnetic induction.

• Surface Insulation Treatment: An insulating coating is applied to prevent short circuits when the steel plate is in use, improving safety and reliability.

Tel:+86 13931106889 / +86 19717485888

WhatsApp:+86 13931106889 / +86 19717485888

Facebook:+86 19717485888

Wechat:+86 13931106889

Email:13931106889@hbxinbian.com

Address:Chang'an Town North Zhougua Village, Gaocheng District, Shijiazhuang City, Hebei Province